Introduction

In the rapidly evolving world of industrial automation, ultrasonic sensors have emerged as a significant advancement. These sensors use sound waves to detect objects, measure distances, and monitor levels, making them indispensable in various applications. From ensuring precision in manufacturing to enhancing safety in packaging, ultrasonic sensors are revolutionizing the industry.

In this article, we will explore the workings of ultrasonic sensors, explore their historical development, and show their diverse applications in industrial automation. We will also mention leading manufacturers, such as MaxSonar, and discuss the future trends in ultrasonic sensor technology. By the end of this article, you will have a comprehensive understanding of why ultrasonic sensors are crucial for modern industrial processes.

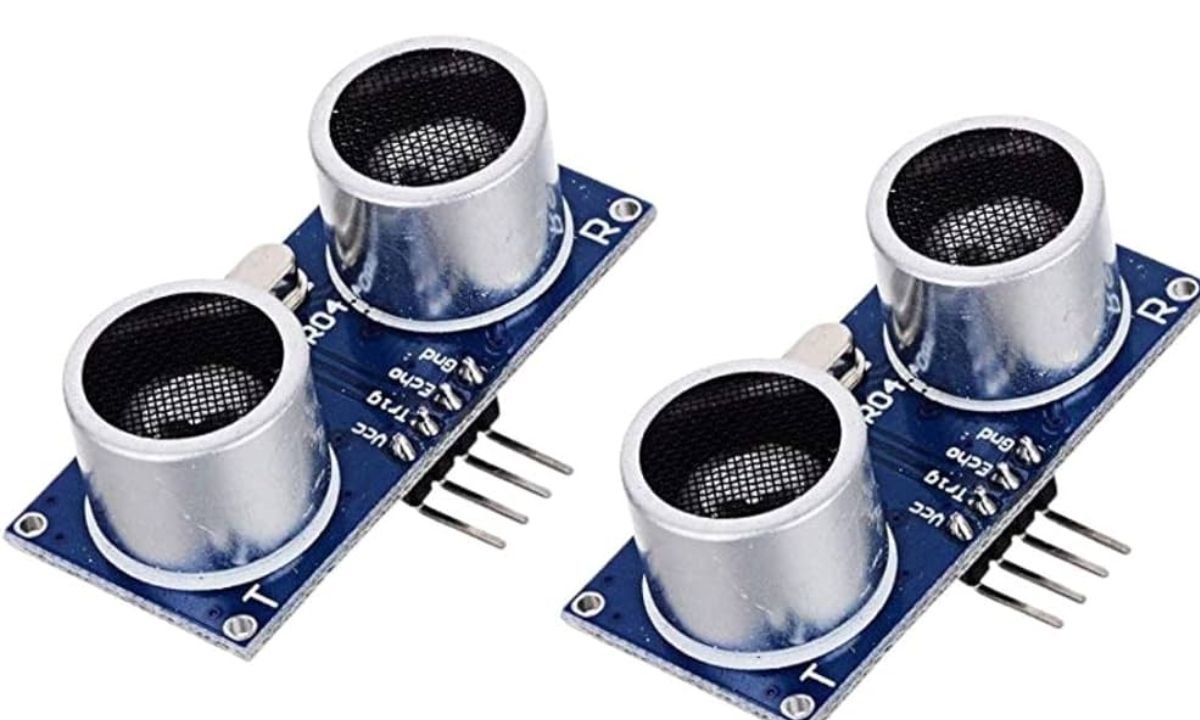

What is an Ultrasonic Sensor?

Ultrasonic sensors operate on a simple and effective principle: they emit sound waves at a frequency that humans cannot hear. These waves travel through the air until they hit an object and then return to the sensor. By measuring the time it takes for the waves to return, the sensor can measure the distance to the object.

For a detailed understanding of how ultrasonic sensors work, you can refer to this introductory guide to ultrasonic sensors.

Here’s a quick rundown of how ultrasonic sensors measure distance and detect objects:

- Emission: The sensor emits ultrasonic waves.

- Reflection: The waves reflect off an object.

- Reception: The sensor receives the reflected waves.

- Calculation: The sensor measures the distance based on the time taken for the waves to return.

Ultrasonic sensors are very reliable and can work in different environments, making them great for industrial use. They are particularly useful in situations where optical sensors might fail due to dust, smoke, or other visual obstructions.

The History and Evolution of Ultrasonic Technology

Ultrasonic technology has a rich history that started in the early 20th century. Initially, it was used in naval applications during World War I for submarine detection, which laid the foundation for future developments. Over the decades, the technology changed a lot, being used in various fields including medical diagnostics, industrial automation, and consumer electronics.

Important moments in the history of ultrasonic technology include:

- 1920s: Development of the first practical ultrasonic submarine detection system.

- 1940s: Introduction of medical ultrasonography.

- 1960s: Commercialization of ultrasonic sensors for industrial use.

- 1980s: Advancements in miniaturization and sensor accuracy.

- 2000s: Integration with digital systems and IoT technologies.

For more information on the history of ultrasonic technology, you can visit ScienceDirect.

Applications of Ultrasonic Sensors in Industrial Automation

Ultrasonic sensors have become essential in industrial automation, offering accurate and dependable solutions for various applications.

Typical industrial uses of ultrasonic sensors include:

- Manufacturing: Used for detecting objects on assembly lines, ensuring components are correctly positioned.

- Packaging: Help in measuring the fill levels of bottles and containers, ensuring consistent packaging quality.

- Quality Control: Employed to detect flaws or inconsistencies in products, maintaining high standards of quality.

Specific types of ultrasonic sensors, such as the ultrasonic distance sensor and sonar sensor, are designed for these applications. The ultrasonic distance sensor is especially useful for measuring the distance between objects with high precision, while the sonar sensor is excellent for detecting objects in hard environments.

Leading Ultrasonic Sensor Manufacturers

In the world of industrial automation, several companies are notable as top ultrasonic sensor manufacturers. These companies are leading in technology, producing sensors that are dependable, precise, and flexible. Here are some of the leading names:

- MaxSonar: Known for their high-quality ultrasonic sensors, MaxSonar has been an important company in the industry. Their products are used in a wide range of applications, from robotics to industrial automation. For more details, you can visit their website here.

- Sick AG: A world leader in sensor technology, Sick AG offers a variety of ultrasonic sensors designed for various industrial needs.

- Honeywell: With many years in manufacturing sensors, Honeywell provides ultrasonic sensors that are known for their strength and accuracy.

- Pepperl+Fuchs: Focused on automation technology, Pepperl+Fuchs offers modern ultrasonic sensors that help increase efficiency and safety in industrial settings.

These ultrasonic sensor manufacturers play a crucial role in improving the technology, making it easier to use and efficient for various industries.

Case Study: MaxSonar’s Impact on the Industry

Their new products and solutions have created new standards in industrial automation. Let’s take a closer look at how MaxSonar has impacted the industry:

Innovative Products

- MaxSonar-WR Series: These sensors are designed for outdoor and industrial applications, offering great accuracy and reliability even in harsh environments.

- MaxSonar-EZ Series: Ideal for indoor applications, these sensors provide accurate distance measurements and are simple to use in various systems.

Successful Implementations

MaxSonar’s sensors have been successfully implemented in numerous projects:

- Robotics: MaxSonar sensors are widely used in robotics for obstacle detection and navigation, improving the performance and safety of robotic systems.

- Manufacturing: In manufacturing, MaxSonar sensors help in watching and controlling production processes, making sure of high quality and efficiency.

- Smart Agriculture: These sensors are used in smart farming to watch crop growth and environmental conditions, helping with more sustainable farming.

Customer Testimonials

Customers have praised MaxSonar for their great products and excellent customer service:

“MaxSonar sensors have changed our manufacturing process. The accuracy and reliability of their sensors have greatly improved our production efficiency.” – A satisfied customer

MaxSonar keeps innovating and leading in ultrasonic sensor technology, making a big impact on the industry.

Beyond Industrial Use: Ultrasonic Sensors in Other Fields

Ultrasonic sensors are very flexible and find applications beyond industrial automation.

One important area where ultrasonic sensors excel is in medical diagnostics. They are used in ultrasound machines to create images of inside body parts. This technology helps doctors find and watch medical conditions well. For more detailed information on this application’s benefits for healthcare, you can refer to this study by Research Gate on ultrasonic transducers for medical diagnostic imaging.

Other uses include:

- Automotive: Ultrasonic sensors are used in parking assistance systems, helping drivers avoid things and park safely.

- Robotics: These sensors help robots move around by detecting objects and measuring distances.

- Consumer Electronics: Devices like smartphones use ultrasonic sensors for features like proximity sensing and gesture recognition.

The wide range of applications highlights the adaptability and importance of ultrasonic sensors in various industries.

Future Trends in Ultrasonic Sensor Technology

The future of ultrasonic sensor technology looks promising, with several new trends and advancements on the horizon. These developments aim to improve sensor performance and expand their applications even further.

Key future trends include:

- Better Accuracy: Advances in sensor technology are leading to more precise measurements, which is important for uses needing high accuracy.

- Miniaturization: Sensors are becoming smaller, allowing for use in small devices and systems without compromising functionality.

- Integration with IoT: The Internet of Things (IoT) is changing how devices talk to each other. Ultrasonic sensors integrated with IoT enable live data collection and analysis, improving automation and decision-making.

Possible new uses and industries that could benefit from these advancements include:

- Agriculture: Precision farming can use ultrasonic sensors to watch crop health and use resources better.

- Smart Cities: Cities can benefit from sensors in traffic management, waste management, and environmental monitoring.

- Healthcare: Beyond diagnostics, ultrasonic sensors can be used in wearable health devices to watch vital signs all the time.

These trends indicate a bright future for ultrasonic sensors, with new ideas making them more popular across diverse sectors.