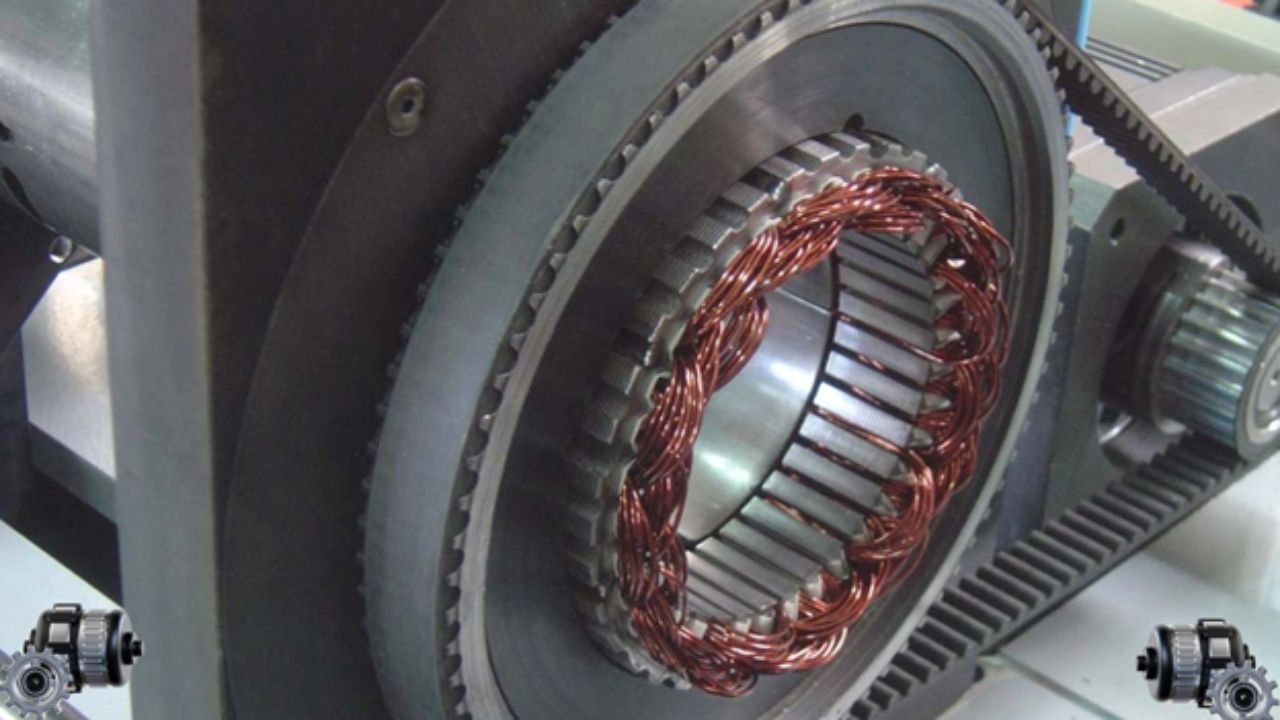

Stator winding machines are basic devices in the development of electric engines, generators, and transformers. These machines are intended to twist wire around stator centers, which are fundamental for making the electromagnetic fields required for engine activity. Nonetheless, similar to any modern hardware, stator winding machines can experience different issues that influence their exhibition and efficiency. Normal upkeep and investigating are fundamental for keeping these machines working at top proficiency. In this article, we will talk about a few normal issues with stator winding machines and give answers for fixing them.

1. Wire Breakage

Wire breakage is perhaps the most incessant issue experienced while utilizing a stator winding machine or needle winding machine. This issue can happen for a few reasons, including exorbitant strain, low-quality wire, or inappropriate settings on the machine.

Causes:

- Extreme strain: In the event that the wire pressure is set excessively high, it can make the wire snap during the winding system.

- Harmed wire: Low-quality wire or harmed wire can likewise add to breakage.

- Machine misalignment: Misalignment of parts like the wire feeder can prompt lopsided strain, making the wire snap.

Solutions:

- Change the pressure settings: Guarantee that the wire strain is appropriately aligned by the sort of wire being utilized.

- Review the wire quality: Consistently utilize excellent wire and examine it for any apparent harm prior to stacking it into the machine.

- Adjust the machine parts: Guarantee that the wire feeder and guide rollers are appropriately adjusted to forestall lopsided strain and decrease the risk of breakage.

2. Improper Winding Pattern

One more typical issue with stator winding machines is a mistaken winding example. This issue can influence the presentation of the engine and lessen the productivity of the winding system.

Causes:

- Inaccurate machine settings: If the machine settings, for example, pitch, turns per curl, or winding point, are not accurately changed, the winding example might be off-base.

- Defective programming: Assuming the stator winding machine is programmable, erroneous program settings can prompt winding blunders.

Solutions:

- Recalibrate the machine: Twofold really look at all machine settings, including the quantity of turns, pitch, and wire arrangement, to guarantee they line up with the expected winding example.

- Update the programming: For needle winding machine that utilize PC-controlled programming, guarantee that the program is accurately placed to match the plan determinations.

3. Machine Jamming

Stator winding machines can encounter sticking, which happens when the wire or the parts of the machine become stuck, keeping the twisting system from going on without a hitch.

Causes:

- Wire misalignment: On the off chance that the wire isn’t taken care of accurately into the machine, it can cause a jam.

- Overburden machine: Overburdening the machine with a lot of wire or twisting an excessive number of curls immediately can make the machine jam.

- Flotsam and jetsam and soil: Collection of trash or soil inside the machine can prompt blockages and cause the twisting system to end.

Solutions:

- Check the wire feed: Guarantee that the wire is taken care of accurately and easily into the machine, without any wrinkles or tangles.

- Abstain from overburdening: Follow the maker’s proposals for load cutoff points and winding velocities.

- Normal cleaning: Clean the machine routinely to eliminate any soil or trash that could impede the winding system.

4. Inconsistent Coil Quality

Conflicting loop quality, like lopsided wire appropriation or free curls, can influence the exhibition of the injury stator and lead to engine shortcomings or disappointments.

Causes:

- Unfortunate machine adjustment: On the off chance that the machine isn’t as expected aligned, the winding system might be conflicting, prompting lopsided loops.

- Conflicting wire feed: Varieties in the wire feed can make loops be twisted freely or unevenly.

- Mileage on machine parts: As the machine parts, for example, the loop previous, age, they might become worn, influencing the consistency of the curl winding.

Solutions:

- Align the machine consistently: Standard adjustment checks will guarantee that the winding machine is working inside the right boundaries.

- Review wire feed and pressure: Guarantee the wire is taken care of uniformly and reliably, with appropriate strain kept up with all through the winding system.

- Supplant worn parts: intermittently investigate the machine for broken-down parts like rollers or guides, and supplant them when essential.

5. Overheating

Overheating is another issue that can happen with stator winding machines, particularly during high-volume or consistent activities.

Causes:

- Abuse of the machine: Delayed use without adequate rest periods can make the machine overheat.

- Unfortunate ventilation: The absence of legitimate ventilation can prompt a gathering of intensity inside the machine, influencing its presentation.

- Electrical issues: Breakdowns in the electrical framework, like a short out, can cause overheating.

Solutions:

- Screen working time: Try not to abuse the machine for extended periods. Guarantee that it has satisfactory cooling breaks.

- Further develop ventilation: Guarantee that the machine is set in a very well ventilated region and clean air channels consistently to forestall overheating.

- Actually look at electrical frameworks: Consistently review the electrical parts to guarantee there are no flaws that could prompt overheating.

6. Excessive Vibration

Inordinate vibration during the activity of a stator winding machine can prompt unfortunate winding quality and expanded wear on machine parts.

Causes:

Imbalanced machine parts: Broken down or skewed parts can prompt uneven characters, bringing about vibration.

Free screws or clasps: On the off chance that screws or latches are free, the machine might vibrate during activity.

Solutions:

- Check for free parts: Assess the machine routinely for any free parts and fix them to decrease vibration.

- Balance the machine: Guarantee that the parts are appropriately adjusted and adjusted to forestall awkward nature that leads to vibration.

7. Software and Control System Failures

Stator-winding machines that depend on programming and mechanized controls can encounter disappointments in the framework, prompting blunders or complete closures.

Causes:

- Programming errors: Like any PC framework, the product controlling the winding machine can encounter errors or bugs that disturb the interaction.

- Equipment glitches: The control board or wiring might encounter gives that keep the machine from working appropriately.

Solutions:

- Update programming: Guarantee that the machine’s product is cutting-edge to forestall errors or mistakes in programming.

- Examine control frameworks: Routinely check the control board, wiring, and sensors for issues that might cause framework disappointments.

Conclusion

Stator winding machines, whether they are programmed or needle winding machines, are fundamental in the assembling system of engines and other electrical parts. Resolving normal issues like wire breakage, ill-advised winding examples, sticking, and conflicting curl quality is pivotal for keeping up with machine productivity and guaranteeing great items. Normal upkeep, legitimate adjustments, and ideal fixes can essentially decrease personal time and increment the life expectancy of these machines. By remaining proactive in resolving these issues, makers can upgrade their creation processes and keep away from exorbitant postponements.